Features

- Very compact and light bypass oil cleaners, specially designed to clean engine oil in a bypass loop; but also a perfect solution to clean diesel fuels.

- Effectively removes all the particles that are not removed by the conventional filters, and performs a total cleaning of the oil by removing solid particles (carbon, metallic particles) absorbing water and eliminating sludge and other oil oxidation residues.

- An absolute necessity when running on bio-fuel! Typically the bio-fuel will mix with the engine oil and create resinous substances that will harm the engine, even leading to engine breakdown, and considerably reduce oil life. Triple R will clean the oil, stabilise the oil condition, and consequently avoid and eliminate the creation of resinous substances.

- Low running cost, easy installation & maintenance.

- Also applicable for lube systems, gearboxes and machinery with a system pressure below 6 bar. For example: wind mills, transmissions, etc.

Setup

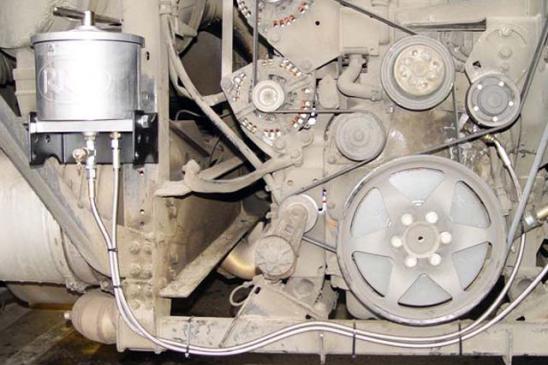

The TR bypass filter connects directly to the engine main gallery, and the cleaned oil is returned to the engine oil pan. Additionally the AL50 and AL100 are ideal to filter the contaminated diesel fuel, especially for engines using high pressure fuel injection pumps.

Case Studies

Download the Van Werven case studie

Download the Volvo engine test

Technical Specifications |

||

|---|---|---|

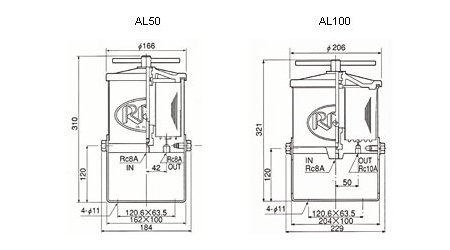

| Model | AL50 | AL100 |

| Article nr. | TR-10300 | TR-10450 |

| Max pressure | 6 bar | 6 bar |

| Engine oil volume | max 15 lit. | max 30 lit. |

| Max flow rate | 2,2 l/m | 3,8 l/m |

| Thread In/Out | 1/4" x 1/4" BSPT | 1/4" x 3/8" BSPT |

| Element type | E50, X50 | E100, X100, D100 |

| Weight kg | 3,5 kg | 5,5 kg |

Special version for windmill gearboxes

Windmill gearboxes are a perfect application for a Triple R bypass oil cleaner. Triple R designed a special series for that purpose that allows longer oil life and reduces wear by removing solid particles, water, moisture and oxidation byproducts. The perfect "all-in-one" oil cleaning solution.

Send your request to Triple R Europe to get our windmill information package.

Download the Windmill data sheet

Filter element & oil change recommendations for engine oil |

||||||||

|---|---|---|---|---|---|---|---|---|

| AL50 | AL100 | Oil Life | ||||||

| Filter model | E50 | X50 | Main filter | E100 | X100 | D100 | Main filter | Max. |

| Routed bus; short dist. | 3.000 - 4.000 km | 4.500 - 6.000 km | 40.000 km | 6.000 - 8.000 km | 9.000 - 12.000 km | 12.000 - 16.000 km | 40.000 km | 120.000 km |

| Tour bus; long dist. | 5.000 - 6.000 km | 7.500 - 9.000 km | 50.000 km | 10.000 - 12.000 km | 15.000 - 18.000 km | 20.000 - 25.000 km | 50.000 km | 150.000 km |

| Short/mid distance truck | 3.000 - 4.000 km | 4.500 - 6.000 km | 40.000 km | 6.000 - 8.000 km | 9.000 - 12.000 km | 12.000 - 16.000 km | 40.000 km | 120.000 km |

| Long distance truck | 5.000 - 6.000 km | 7.500 - 9.000 km | 50.000 km | 10.000 - 12.000 km | 15.000 - 18.000 km | 20.000 - 25.000 km | 50.000 km | 150.000 km |

| Dumper/cement truck | 3.000 - 4.000 km | 4.500 - 6.000 km | 40.000 km | 6.000 - 8.000 km | 9.000 - 12.000 km | 12.000 - 16.000 km | 40.000 km | 120.000 km |

| Fork lift, container lift, etc. | 125 hr | 175 hr | 500 hr | 250 hr | 350 hr | 500 hr | 500 hr | 2.000 hr |

| Fork lift, container lift, etc. | 125 hr | 175 hr | 500 hr | 250 hr | 350 hr | 500 hr | 500 hr | 2.000 hr |