Features

High capacity solid particle and sludge removal, for

- Water based fluids, emulsions and process water.

- Oil based fluids up to max 20 cSt. viscosity at operating temperature.

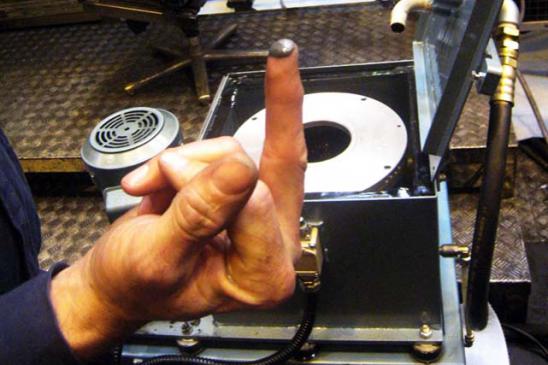

- The centrifuges provide highly efficient and reliable liquid/solids separation capability and virtually dry solids discharge without the use of consumable filtration elements.

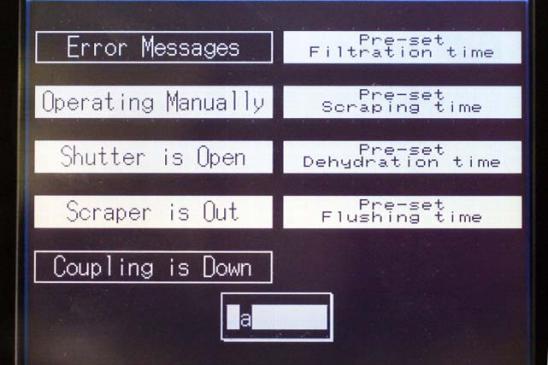

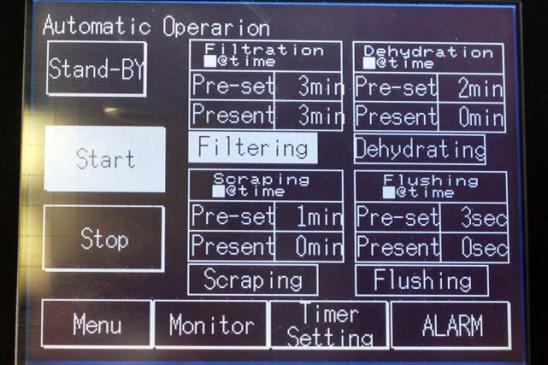

- Available with manual operation, or full automatic with touch screen control panel and build-in dirt scraper. The open conic bowl concept allows easy cleaning and removal of the separated dirt. Low maintenance cost.

- Flow rates from 15 lit/min up to 200 lit/min. No consumables, one-time investment.

Typical applications

- Coolants for metal, glass or ceramic machining or forming.

- Surface treatment baths and parts washers, like washing steel plates in metal stamping.

- Paint shop water.

- Metalworking, metals pretreatment, wire drawing.

Benefits

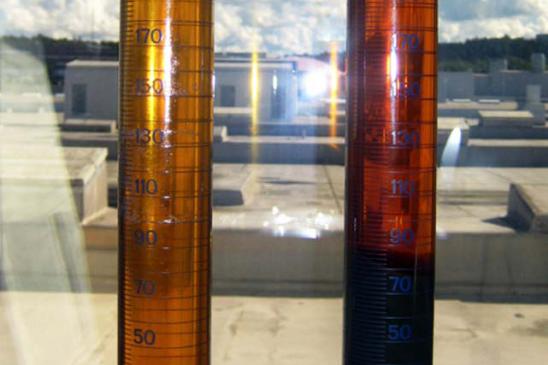

- Separates micron sized particles, such as aluminum/steel dust, carbon, lens and glass dust, stone dust and mud.

- Dehydrates and solidifies sludge.

- Improves machine reliability and product quality.

- Increases production speed and productivity.

- Extends useful life of coolants and oil; reduces coolant and oil consumption and prevents deterioration of the fluid. Additives will not be separated.

- Important reduction of maintenance costs.

Technical specifications manual centrifuges |

||||||

|---|---|---|---|---|---|---|

| Model | Motor | Power | Max. flow | DRPM | Dimensions | Weight |

| TRS30-M | 400V x 3 - 50 Hz | 0,75 KW | max. 30 l/m | 2.810 | 300 x 500 x 377 | 55 kg |

| TRS50-M | 1,5 KW | max. 50 l/m | 1.881 | 300 x 650 x 422 | 100 kg | |

Technical specifications automatic centrifuges |

||||||

|---|---|---|---|---|---|---|

| Model | Motor | Power | Max. flow | DRPM | Dimensions | Weight |

| TRS100-A | 400V x 3 - 50 Hz | 3,70 KW | 100 l/m | 3.000 | 630 x 1100 x 1768 | 650 kg |

| TRS200-A | 5,5 KW | 200 l/m | 2.500 | 730 x 1200 x 1768 | 750 kg | |