TRIPLE R oil cleaners have an immediate impact on the machine running costs.

TRIPLE R bypass oil cleaners deal with Oil Contamination by:

|

Removing up to 99% of all solid contaminants (NAS 5 or better) | |

|

Reducing the water concentration to less than 100PPM | |

|

Eliminating varnish and oxidation products |

The outcome is a tremendous package of benefits!

- An important reduction in erosion, fatigue, abrasive wear and wear of critical clearances.

- Stabile oil viscosity and acidity and perfect lubricating properties.

- Increased fluid life by up to 10 years or 50.000 hrs.

- Significant reduction of oil consumption and oil disposal cost.

- No coating or corrosion of metal surfaces and no generation of rust.

- No blocking of full flow filters with cold oil; the famous Monday Morning Disease.

- Best possible operation of the heat exchange and oil coolers.

- Reduced power consumption.

- Increased machine performance, controllability, system efficiency, reliability and machine life.

- Longer life for hydraulic components (pumps, valves, cylinder seals and other spare part).

- An important decrease of machine down time, manpower and production loss.

- 2 to 4 times lower use of expensive full flow filter cartridges.

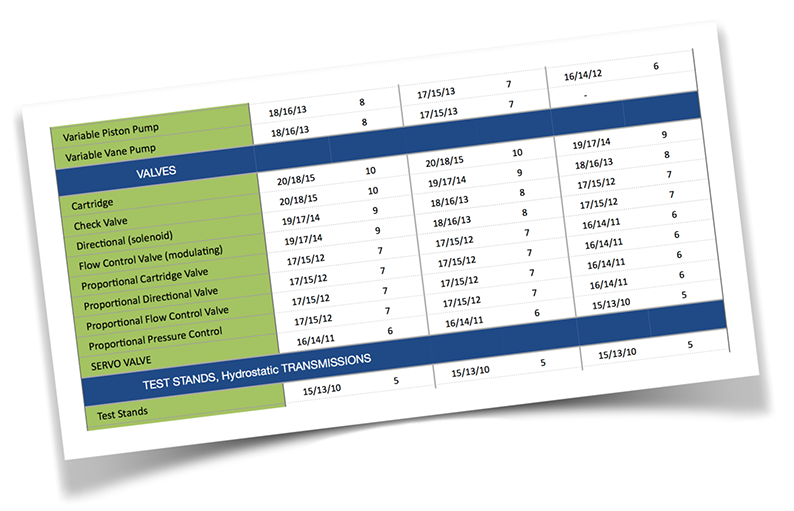

The International Oil Cleanliness recommendations. Check and set your targets.

Every system requires a certain level of cleanliness. The degree of cleanliness greatly depends on the type of components fitted on your machinery.

We recommended to check what type of components you have on your machinery and to set your oil cleanliness targets accordingly. Download the file below and compare with the cleanliness you have today.

Remember, though: new fresh oil doesn't come clean. Very often your fresh oil is already too contaminated to run on machinery, like for test stands or hydraulic systems steered by servo valves.