TRIPLE R doesn't sell oil filters, but the guarantee for perfectly

cleaned oil. No false promises, only guaranteed results.

Do you need an oil filter for improving your oil cleanliness?

No problem, you can probably find a filter supplier on every corner nowadays.

But what's the point if you don't know if that filter will keep your lubricants clean?

Triple R differentiates itself from all other filter suppliers by guaranteeing PERFECTLY CLEAN OIL!

Whatever the application, whatever the contamination level, with a Triple R bypass oil cleaner you can rest assured that you buy a solution for your contamination problem.

35 years of experience and continuous R&D made Triple R to be thé reference when it comes to bypass oil filtration.

All TRIPLE R filter elements are tested according to the Multipass Test ISO 4572.

Meaning that every µ-rating and beta value we state, results from extensive testing performed by an official and certified Multipass Test Laboratory.

Our µ-ratings are always ABSOLUTE (beta x > 75) and never an "irrelevant" NOMINAL value.

Be cautious of counterfeit and untruthful bypass filter manufacturers/suppliers claiming absurd 0,1 µ filter ratings, 2kg of particle and 2 liters of water absorption capacities!

It can save you a lot of trouble afterwards.

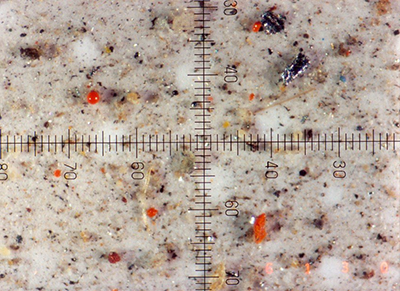

Without bypass filtration

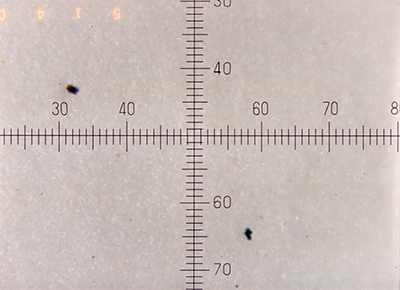

With Triple R

Have a Triple R bypass filter fitted on every single machine and save big from all the benefits!

With Triple R bypass filters you can keep your oil continuously clean and benefit from all the advantages:

- Longer oil life : increase oil life even up to 50.000 hrs (hydraulic systems) or 2.000 hrs (engine motor oil).

- No pump and valve breakdown : reduce parts failures by >90%!

- Increased life of the expensive full flow filters : they will last from 2x up to 5x longer.

- No sudden or not scheduled machine standstill and production loss; increase production capacity.

Contaminated oil causes 90% of machine faults and downtime!

Hydraulic fluids lie at the heart of any type of manufacturing equipment. This oil must be filtered, analysed and replaced. And despite all this, companies still suffer downtime during which pumps, valves, cylinders and seals need to be replaced. Pollution in the oil cannot be avoided and is an integral part of every hydraulic system.

Even new hydraulic fluid is dirty, and typically contains more than 75,000 solid particles > 5µ per 100ml. Pumps, valves, pipes, hoses, heat exchangers and oil tanks all bring dirt from the manufacturer.

Abrasive wear, fatigue and erosion all cause additional contamination whenever dirt particles circulate through the system at high speed and at high pressure. Dirt particles from the surrounding air, entering through reservoir breathers and cylinders rod seals, add to the system's contamination load.

Condensation caused by changes in temperature and leaking oil cooling systems contaminate the oil with water. A combination of metal particles (which act as catalysts), water and oxygen at relatively high temperatures will result in increased and accelerated oxidation of the oil.

During this complex process of oxidation, polymerisation causes sticky molecular structures, which we normally call sludge.

These resinous substances are dark in colour (one of the reason why oil darkens after a period of time) and leave deposits on all the many parts of the hydraulic system.

Due to their microscopic size, they are not removed by traditional filter systems, and because of their sticky structure and corrosive effect, they directly affect the efficiency and the reliability of the hydraulic system.